By: Judit Monis, Ph.D. – Vineyard and Plant Health Consultant

The National Clean Plant Network (NCPN) is a USDA funded program focused on specialty crops such as berries, citrus, grapevines, fruit trees, hops, roses, and sweet potatoes. The clean planting material is to be distributed to nurseries for further propagation and distribution to growers. The NCPN operates under high standards for the production of true-to-type and pathogen-tested (mainly viruses) plant material. The branch of the NCPN that focuses on grapevines (wine, table, and raisin) met on January 26 in Davis, CA and virtually. Grape Clean Plant Centers are located in California, Florida, Missouri, New York, North Carolina, and Washington States. Representatives of the clean centers, as well as members of the grape industry, extension, State and US regulators participated in the meeting. Each of the Clean Plant Center directors presented an update highlighting last year’s activities. In addition, a few presentations focused on NCPN business, strategic plan, economic research on the return of investment of clean centers, and extension activities. Here I summarize the highlights of the discussions.

The NCPN Strategic Plan (2023-2028)

Before I describe the strategic plan, I will define and clarify what are G1 clean plants propagated at any of the clean plant centers. The first generation of plants propagated in a clean plant center is known as a G1 plant. Plants propagated from G1 are known as a G2 plants, plants propagated from G2 plants are G3 plants, and so on. Under NCPN, a clean plant is defined as one that has been tested at the G1 level for viruses and certain pathogens of economic importance (the pathogens were not detected). Note that so far more than 101 viruses have been reported in the grapevine crop, and only a few of these viruses are of economic importance. NCPN also tests for the bacterial pathogen Xylella fastidiosa and certain phytoplasmas.

There are five goals in the NCPN strategic plan: security, redundancy, capacity, availability of tested plant material, and sustainability. Security refers to NCPN ensuring that G1 stock propagated in clean centers are free of economically important viruses by utilizing standard operating procedures for testing and to prevent reinfections. Redundancy applies to the need of having at least two different plants of commonly planted cultivars and rootstocks in at least two different locations. Capacity pertains to the development of an inventory of the plants propagated in each clean plant center and determine the priorities of selections needed to be protected nationwide. Availability refers to the need of having plant material tested for economically important viruses available. Finally, sustainability relates to the assurance that the program meets financial and fiscal stability and the support from NCPN is not higher than 30% of the total center’s budget. In other words, each center is expected to procure financial support to carry out the clean plant activities (user service fees, other grants, etc.).

Highlights of Clean Plant Center Director Updates

California: Maher Al Rwahnih, Foundation Plant Services in Davis, reported that the Classic Foundation Block (an older block planted in the field at UC Davis) continues to test free of Grapevine red blotch (GRBV) and Grapevine leafroll -3 (GLRV-3) viruses. The completion of a greenhouse in Davis has allowed to move plant material to be protected from insect vectors and potential virus transmission. Funding is being procured from the industry to build a second greenhouse as NCPN does not fund construction of buildings or any infrastructure.

Washington: Scott Harper, Clean Plant Center North West reported on the removal of the outdoor foundation block due to the infestation of dagger nematodes and Tobacco (TRSV) and Tomato ringspot virus (ToRSV) infection is some of the accessions. At the moment, the only available foundation block is planted in a screenhouse with regular testing for the presence of GRBV, GLRV-3, and Xylella fastidiosa. In addition, the foundation was subjected to the testing of TRSV and ToRSV due to the outdoor infestation findings stated above.

Missouri: Sylvia Peterson and Wenpin Qiu, Midwest Center, reported that all of their G1 plants are hosted indoors in a greenhouse were subjected to RNA-seq HTS. The results of the two positive findings (GLRaV-2 and GLRV-3) were verified by RT-PCR.

North Carolina: Christie Almeyda, Muscadine Grapes Clean Program, reported that all plants are hosted in triplicate in a screenhouse and tested for 13 different pathogens. Plants were distributed in Arkansas and North Carolina. The program NCPN funding has fluctuated throughout the years and stresses the importance of locating supplementary funding to run clean plant programs.

Florida: Violeta Tsolova, Muscadine/Southern Grapes reported hosting and maintaining a G1 outdoor Muscadine and Pierce’s Disease tolerant interspecific hybrids (3-12 plants) and a single plant of each in a screen or greenhouse. New plants are tested for 19 viruses and Xylella fastidiosa. The G1 foundation is tested yearly for leafroll, red blotch, and Grapevine virus B.

New York: Marc Fuchs, The North East Clean Plant Center at Cornell University, reported that the center does not host a G1 foundation. The center has focused their activities in the introduction, therapeutics, and release of a number of accessions.

Economic Studies on the Advantage of the Clean Plant Programs

Jie Li from the Dyson School of Economics and Management Department at Cornell University lead a discussion on the need for more economic studies related to the use of clean planting material. A study was completed by Dr. Li and colleagues that analyzed the activities performed at the Foundation Plant Services program at the University of California at Davis. The study focused on the return of investment of producing and distributing grapevine leafroll disease tested plant material to nurseries planted by growers in different regions in California between 2006 and 2019. The results showed that depending on the disease incidence estimated, the hypothetical return of investment was 1:22 (assumes a 5% leafroll disease incidence) or 1:96 (assumes a 20% disease incidence). In other words, $1 spent to produce plants at FPS yielded $22 or $96 in return, assuming a 5 o 20% disease incidence, respectively. The research identified the main beneficiaries were the nurseries, but logically the benefits ultimately trickled down to growers and wineries. The discussion led by Dr. Li was done to determine how to design other studies that would focus on additional clean plant centers and other diseases (i.e., red blotch, Pierce’s disease, etc.).

Production of NCPN Extension Videos

Cain Hickey, viticulture extension educator at Pennsylvania State University, lead a discussion on the potential of developing informative videos focusing on different aspects of the NCPN program. The Pennsylvania State University in cooperation with Cornell University already produced four videos describing the NCPN program, grapevine certification and clean planting stock, as well as other regional focused viticulture issues such as delayed pruning, spring freeze vine protection, etc. The videos can be viewed following the link: https://extension.psu.edu/answers-from-the-vineyard-winery-and-tasting-room.

The group brainstormed ideas on future video productions that could focus on: virus elimination methods, crown gall and fungal pathogens, grower testimonials on the use of clean planting stock, definition of G1 and G2 plants, disease spread in the vineyard, etc.

Conclusions

It is important to understand that a clean plant is one derived from a plant that has been tested for a number of economically important viruses and certain pathogens and the target pathogens were undetected. It does not mean that the plants are free of all pathogens. Most of the clean plant centers do not test or exclude fungal trunk disease pathogens or Agrobacterium vitis (the causal agent of grapevine crown gall). In no way it means that that nursery material derived from plants released from a clean plant center will always be clean (pathogen-free). There are still challenges for maintaining a virus-free grapevine plant collection. It is good to see that NCPN is moving towards having redundancy on the grapevine variety collection. This will ensure that if there is a disease outbreak in one of the centers, another center will have the plant material available for easy replacement.

There was agreement from both participating NCPN and nurseries that currently it is not possible to certify vines free of Agrobacterium vitis. This is important to point out particularly in cold climate grapevine growing areas prone to freezes. But in my experience, I have seen vines develop galls due to the bacterial infection in California too.

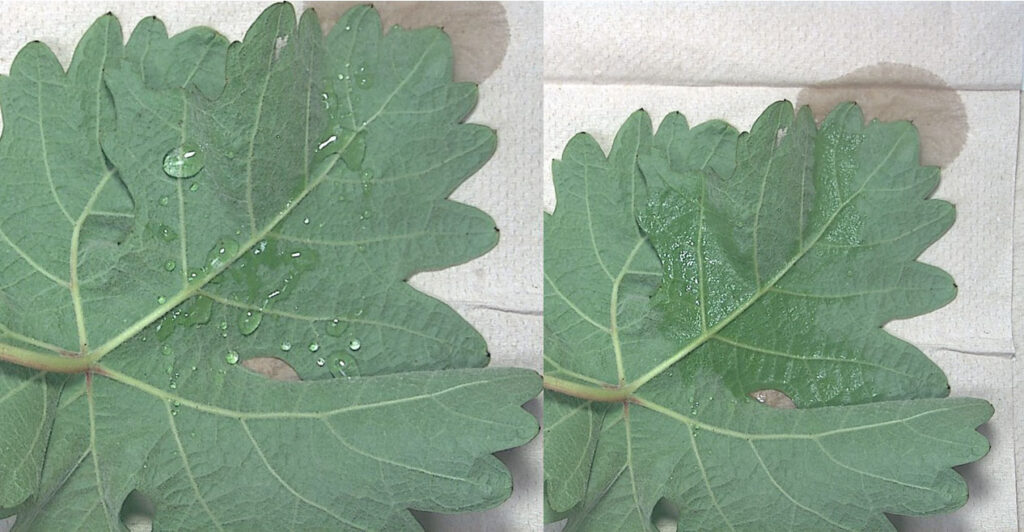

In spite of the limitations of clean plant programs, the use of certified material is less risky than planting field selections of unknown infection status. It is always prudent to test the planting material for important pathogens to verify lack of infection. Last but not least, when developing a new vineyard block it is important to plan in advance. The timely planning will allow inspection of the nursery increase blocks early in the fall (before the leaves fall) as well as the evaluation of the quality of the finished planting product.

Judit Monis, Ph.D. provides specialized services to help growers, vineyard managers, and nursery personnel avoid the propagation and transmission of diseases caused by bacteria, fungi, and viruses in their vineyard blocks. Judit (based in California) is fluent in Spanish and is available to consult in all wine grape growing regions of the world. For more information or to request a consulting session at your vineyard please contact juditmonis@yahoo.com or visit www.juditmonis.com