By: Hanifa Sekandi

Every wine collector believes their collection of vintage wines is nothing like anyone has ever seen. When collectors curate wines, they look for the best and go to great lengths to get their hands on a bottle. If this is you, you may be missing a few rare gems that only those in-the-know truly, know about. Further, some of the rarest wines in the world come with a jaw-dropping price tag and are not easy to come by. Surprisingly, there is no TV show called “Precious Wine Hunters.” Wine represents lost stories that take us back in time, stories that remind us that in every century, people overcome obstacles. Wine is a tribute and notebook of lost times full of lessons. With every bottle, there was either joy or turmoil. Take a trip down vineyard lane and discover the untold stories of vines of the past, the people who toiled on that land and the pain and glory they felt, one crushed grape at a time.

What Makes Wine Rare?

Before we explore the unknown world of wine, it is essential to clarify what classifies a rare wine since we live in an overly social world. With different medians for information, confusion is the norm. It is easy to create an illusion of luxury. Moreover, it is easy to buy into the scarcity effect and assume that something exclusive is rare. Precisely, it has nothing to do with sitting with the cool kids or faking it until you make it. A rare wine stands alone in its glory and does not need pomp and circumstance to catch your attention. It is what it is: rare. So, what makes wine rare? This is a nuanced conversation because a range of factors come into play.

A rare wine may be a bottle that houses exquisite grapes that produce a smaller yield. Such grapes may not grow if conditions are not favorable. Vines spoiled by pests will also produce a smaller yield since few grapes, if any, can be harvested. Hence, it is a rare bottle of wine with a small number of bottles produced. A winery producing a limited amount of select wine can increase the price. Both accessibility and price point can render a wine rare. Another element is time. How long has this wine been stored? For example, a 1774 Vercel “Vin Jaune d’Arbois” was stored close to France’s Jura Mountains in an underground cellar. This wine sold for $120,800 at auction. Both age and it being a rare historic discovery classify this wine as rare.

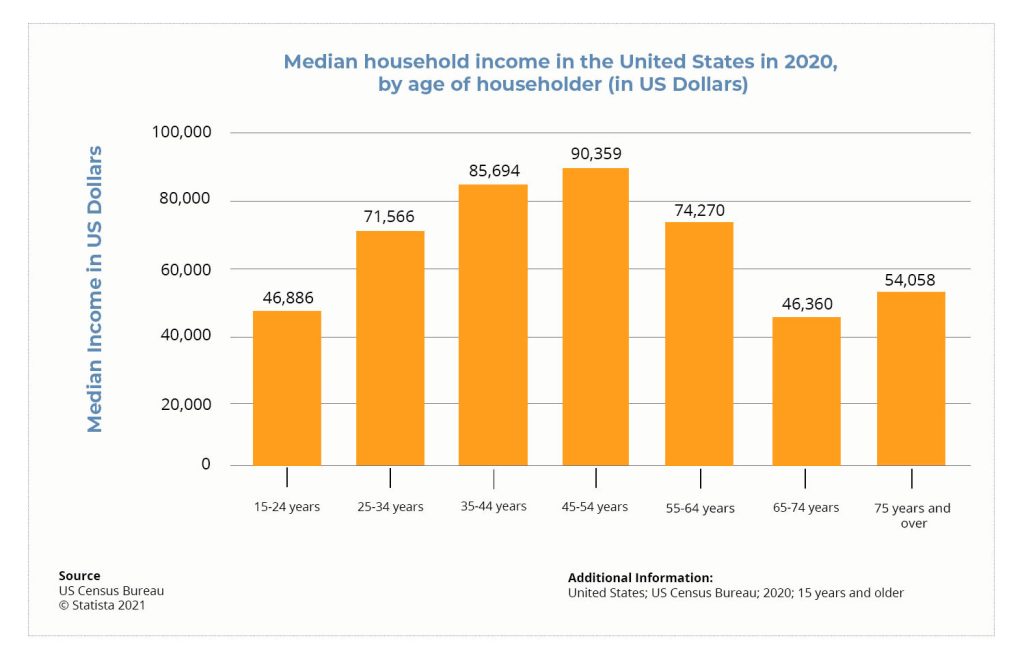

So yes, scarcity does factor into designating a select bottle of wine rare. But there is more to the story. Although, a homebrew wine that you made may be rare for you. It certainly will not have sommeliers lining up to sample or make it to the auction block. The types of grapes contribute to its rarity and the vineyard of origin. Of course, a wine produced from a single vineyard is considered rare. Also, who made it is an important marker. Many viticulturists would agree that the rarer the grape, the better. The 30 grape varieties that are predominately used in 70 percent of the bottles of wine produced worldwide would not be considered rare, per se. When we think of rare, we travel to smaller vineyards that grow vines that are not commonly known. These are wines that not only have a hefty price tag but may only be familiar to those who live close to the vineyards or true precious wine hunters. So, there are elements of exclusivity, scarcity and time determining if a wine is a gem to imbibe or carefully store, to gaze at or boast to friends and fellow collectors.

A Rare Find in Germany

There are many rare finds in the wine landscape, and this is indeed one of them. The vineyard of origin of this bottle of wine found in a Roman soldier’s tomb in 1867 will never be known. There is no way to decipher whether the grapes used are from an elite vine. It is simply called the Speyer bottle of wine. This bottle of wine is touted as the oldest bottle of wine in existence. It rests comfortably on display at the Pfalz Historical Museum in Speyer, Germany. It has remained intact for well over 1,693 years in a 1.5-liter glass bottle with intricately designed dolphin handles.

Inside this well-preserved bottle floats olive oil and herbs, used to preserve the wine or enhance the flavor profile. It is sealed with wax. It dates to 325 C.E, Roman rule, a time when local grapes were used for making wine. The ratio of wine and oil is in favor of oil. Since it was discovered in the soldier’s tomb along with other broken bottles, it may signify an afterlife offering or be placed alongside the deceased for ritual purposes. Can you drink it? According to researchers, although taking a few sips will not kill you, it most likely does not taste particularly good!

The High-Priced Bottles from France’s Jura Region

It is clear that time is a factor in the rarity of wine. The length of time wine has matured or whether it has historical roots matters. Some wines are considered both vintage and rare. A bottle of 1774 Vercel “Vin Jaune d’Arbois sits perfectly in this category. Not only is it a rare wine, but it is also a vintage classic made by legendary winemaker and inventor of vin jaune, Anatoile Vercel. The sale of three bottles in 2018 was put forth by his descendants who live in Arbois. The vineyard where these wines were made is in the eastern Jura region. It was during King Louis XVI’s reign when these bottles’ grapes were harvested, another element that adds to the rarity of this wine.

Can you drink it? How does the oldest wine in the world taste? Fortunately, 24 wine experts who have had the privilege to taste it in 1994 can answer these questions. Yes, it is, as you would imagine it, sublime. They rated it a 9.4 out of 10 and noted that the longer it ages, the better it will get. The experts recommended that the next time it should be tasted is 100 years from now. So, how does it taste? Aromatic notes of cinnamon, spices and curry engulf the senses with a smooth essence of nuts, vanilla and dried fruit. The savagnin, a local grape used to make this wine, is matured in a barrel with a film of yeast. It is also attributed to the yellow coloring.

Secrets in New Jersey

Who would have thought? Certainly, not the people who discovered a case of 1796 Lenox Madeira stowed away at the Liberty Hall Museum. In 2015, during renovations, this imported case of wine was discovered while encased behind carefully plastered walls. How did it get there? And to whom do they belong? Madeira is a Portuguese wine that was illegally smuggled into the United States. John Hancock was a merchant, political leader and an American founding father infamously known for avoiding British tax and smuggling wine on his ship, Liberty. It has been documented that on this very ship, bottles of black-market Madeira were seized, an incident that has been purported to have incited the Boston riots. It was the prohibition era, but Hancock’s bold moves set in motion a new era: the Revolution.

America represented the new world for those who settled. Although, it was a world that already lay rich in culture from the people who walked the land centuries before the ships came to shore. Madeira, a much-loved beverage of the 1700s, carries as much turmoil as it does joy. This was a voyage of promise and the realities of both pain and displacement, but not what the winemakers of the vineyards on this island off the east coast of Morocco foresaw. This viticulture gem is prized for its history and the journey took to foreign lands, another reminder that wine carries both joy and sorrow. Does this wine measure up? As of now, no one has tried it.

There are many unexpected turns in the world of undiscovered rare wines. There is a bottle or case of wine somewhere yet to be discovered. There is a winemaker whose lineage carries prestige or a rare grape only a select few may try. This is what makes wine unique and loved by many. It is an unpredictable beverage shrouded in secrecy and infamy. It is a bit of an anomaly that in modern times, one can casually stroll down liquor store aisles – a remarkable freedom in and of itself. For people of past times looking into the future and seeing the selection of wines on demand, just at your fingertips, this would be a rarity. Every wine, whether prestigious or not, would leave them spellbound.