How AI and Other Technologies Are Changing the Landscape for Vineyards & Wineries Worldwide

By: Cheryl Gray

From grape-picking robots to mechanized pruning machines, just name it, technology has a cutting-edge answer for virtually any vineyard need to reduce dependence upon manual labor.

Studies show that technology-driven equipment is becoming increasingly used in the viticulture industry. When deployed, those studies show that the results show greater productivity when it comes to caring for and, eventually, harvesting grapes.

Westside Equipment Company is one of the corporations at the forefront of making this a reality for its clients. A global leader in its field, Westside Equipment is headquartered in Madera, California in a grape-growing region designated as an American Viticultural Area (AVA) since 1985. The company, which also has three other locations in the Golden State, has been in business for nearly 40 years.

Westside Equipment Company, which designs and manufactures harvesting equipment at its Madera location, recently acquired VMECH for its portfolio, adding an entire new line of technology-driven vineyard products, including the Chariot Mechanized Vineyard Pruner. Stephanie Hawkins is the marketing and sales coordinator for the company.

“The VMECH Chariot’s dual precision pruner adapts to various trellis types and enables pre-pruning and near finish pruning, covering up to three acres per hour and saving up to $600 per acre. With a vision-based approach, our AI technology identifies and scans the cordons, adjusting based on the incoming data. The versatile Chariot has multiple attachment options to keep it useful year-round, including shoot thinning and trunk suckering. A single row pruning unit will be available in fall 2023.”

The Chariot is useful for applications that include work on high wire, VSP and quad trellises. According to Westside, the equipment is built to supplement pruning capacity and comes equipped with individual joysticks for seamless operation. While the machine requires three operators, it promises to save money by pruning two rows at a time and one to three acres an hour, depending on row spacing and length.

Another feature of the Chariot is that its pruning heads are efficient, versatile, and can be customized. The heads attach to each of the machine’s booms. In addition to its pruning capabilities, the Chariot can be used to cane-cut vineyards in spring.

The VMECH Toolbar is another vineyard productivity tool. The unit is designed to be mounted on virtually any tractor, with Westside Equipment providing manufacturing assistance to ensure a proper fit. Customer support, Hawkins says, is important to Westside Equipment.

“All Westside Equipment Company products are custom built at our manufacturing headquarters in Madera, California and come with 24/7 in-season service and parts (limited to California vineyards) to conveniently serve the wine grape industry,” Hawkins said.

For companies that take over when the grapes arrive at the winery, Prospero Equipment Corporation considers itself a frontrunner in supplying processing and packaging equipment for wineries of every size. The company, founded in 1972, started as a supplier to home winemakers.

In the 1980s, Prospero expanded into commercial wine-making equipment, opening an office in California to begin servicing and distributing products from Italy to West Coast wineries. The product roster includes imported tanks, fillers, labelers, commercial presses, filters and crusher destemmers. The family-owned and operated business now specializes in offering the latest technology to help wineries keep pace in an ever-changing industry.

Prospero represents SK Tank, which builds wine tanks, wine presses and equipment for other beverage industry sectors. Andy Robinson represents Prospero’s sales division.

“Working with SK allows Prospero to offer full tank storage capabilities as well as supporting harvest equipment,” Robinson said. “Prospero’s brewhouse division offers the highest quality brewhouses and beer tanks accompanied by full engineered designs and complete turnkey installations.”

Robinson adds that Prospero has recently launched new products that focus on the use of technology, thanks to a newly formed relationship with GAI Machinery, which Prospero now represents.

“GAI sets the upper standard of machine manufacturing and offers the highest quality packaging equipment available,” Robinson said. “Prospero now offers a revolutionary new technology with the UNICA filling valve, which is an Electro Pneumatic filling valve capable of filling from 0 – 6 BAR pressure. This has allowed many companies to expand their product lines and be able to package all of them within the same Monoblock. The UNICA filling valve is now also available with a Volumetric Electro Pneumatic filling valve, offering the most precise filling for a wider range of container sizes and formats. Offering still and counterpressure filling in the same filling valve has brought the new technologies to the forefront of packaging for the beverage imdustry. The UNICA filling valve is also offered on the GAI canning Monoblocks. The GAI Monoblock design is engineered so all main gears are interlocking and connect all turrets, thus eliminating any risk in loss of machine timing.”

Robinson adds that Prospero has multiple ways to help its clients with products and services, identifying the absolute essentials for wineries that want to keep up with the latest technology.

“Prospero offers sales consulting, engineered drawings, parts departments and a technical team for service, installation and training,” Robinson said. “Having effective product and packaging consultation allows direct discussions for future growth and wiser investment strategies. Providing engineered drawings allows for a seamless installation, parts to be on hand if needed and a direct format for our technical team to follow.”

Robinson says that planning ahead is the key to keeping up with technology.

“A company should plan for future development of products and production volumes, this also includes added closures and perhaps canning,” he said. “Investing in high quality equipment helps guarantee longevity, ease in maintenance and the finest quality finished product. Prospero technicians fully train all new equipment owners after installation to guarantee all operators are knowledgeable about the machinery and the supporting equipment. This support is backed up by our service and parts department for maintenance and repairs.”

Experts say that the cost of labor is the biggest expense grape growers face every season. With the declining number of farm workers available to work the vineyards, those experts say there is a serious labor shortage. The answer for many growers is technology replacing workers to do the tasks of pruning, shoot thinning, shoot posting, fruit thinning, leaf removal and row line cultivation.

Gearmore, Inc. specializes in implements for those many operations. Gearmore, Inc. has provided quality vineyard implements through servicing tractor dealers for 60 years. To cover all the grower’s requirements, the company has more than 100 different models, with widths and capacities of products for vineyards to handle varying acreage, row widths, terrain, foliage profile and different tractor horsepower.

Gearmore is headquartered in Chino, California and boasts the largest inventory of implements on the West Coast. Its reach is global and includes sales representatives in charge of territories throughout the southwestern United States, Hawaii and parts of Mexico. Vineyard equipment options include in-row cultivators, air blast sprayers, soil conditioners, air sprayers, boom sprayers, vine trimmers, leaf removers, pre-pruners, compost spreaders, mowers, soil conditioners, mower shredders and more.

There are other technologies in use by vineyards, such as drones, satellite imagery and GPS. Larger operations use these technologies to monitor vineyard health, and smaller vineyards are following suit. Through satellites and drones, vineyards can easily gather data, including the ripeness of grapes, water shortages and the early signs of vineyard disease. The technology can also help protect the environment because products must only be sprayed for disease and pests when necessary.

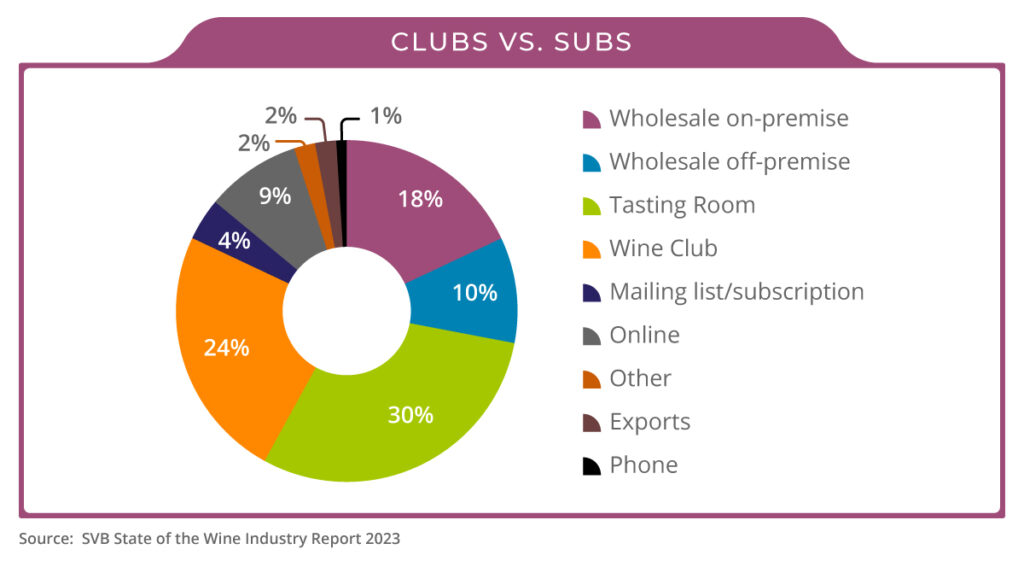

As for wineries, experts say that platforms that merge statistics, such as point of sale, club memberships and e-commerce help streamline sales and improve customer experience.

In short, technology, including AI, is increasingly becoming the norm rather than an anomaly for vineyards and wineries. Its widespread use is now seen as a way to advance productivity and sales in a highly competitive industry where smart moves driven by technology make money.