Page 44 - Grapevine July-August 2019

P. 44

Around The Vineyard

and fabrication led to many of the features and options now

available on the modern day versions of Turbo-Mist Sprayers.

Return on investment, through product reliability and amor-

tization, is something the company touts, as its team points

out that some of its long-time customers are using versions of

Turbo-Mist Sprayers built some 50 years ago.

Careful planning is essential to any farming enterprise and no

less important for vineyards. Slimline Manufacturing revolves

its season around its customers’ needs, adding that its Turbo-

Mist Sprayers play a vital role. Slimline Manufacturing boasts

of a dealer network that teams up with customers well before

harvest time, often up to a year in advance. The goal is to help

these customers achieve optimally planned, well managed and

environmentally sustained spraying practices.

Rachelle Wirth, Marketing & Communications Manager for

Slimline Manufacturing, says the company strives to provide

customers with genuine solutions in real time. “Fuel costs in

many of our customers’ regions are becoming astronomical;

water shortages are becoming the new normal. Operating as if

these issues are going to correct themselves is not an option.”

Wirth says that Turbo-Mist products enable growers to drasti-

cally reduce fuel costs and water use without sacrificing cover-

age, yield or crop quality.

Working in tandem with vineyards to develop new products

is another method by which some manufacturers, including

Slimline, keep pace with customers’ needs. Steve MacDonald

manages some 300 acres under MRS Vineyard Service in Oliver,

British Columbia. “Our spray program is a good example of

using the best equipment,” MacDonald says. “Your starting

point is choosing a sprayer that will deliver the droplet size you

want to where you want it. Slimline Manufacturing...worked

with us to develop a couple of three row machines that are still

as good today as when we purchased them in 2009. Each has

over 15,000 acres under their belts.” MacDonald translates

that coverage into less than five dollars per acre applied capital

cost for a $70,000 machine.

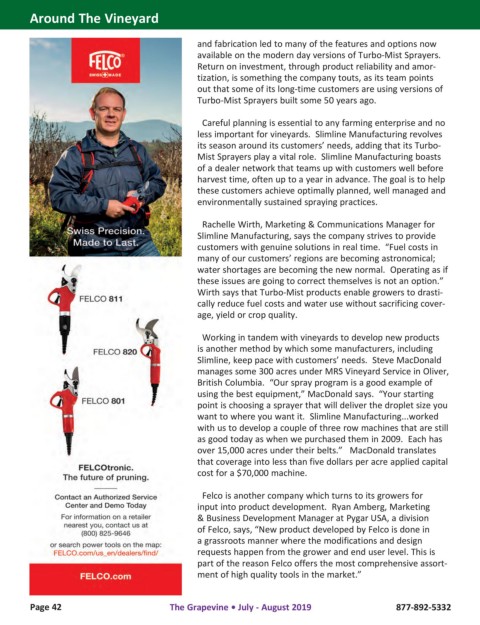

Felco is another company which turns to its growers for

input into product development. Ryan Amberg, Marketing

& Business Development Manager at Pygar USA, a division

of Felco, says, “New product developed by Felco is done in

a grassroots manner where the modifications and design

requests happen from the grower and end user level. This is

part of the reason Felco offers the most comprehensive assort-

ment of high quality tools in the market.”

Page 42 The Grapevine • July - August 2019 877-892-5332

Grapevine Main Pages GV070819_Layout 1-1 .indd 42 6/18/19 3:20 PM