Page 44 - Grapevine Jan-Feb 2020

P. 44

Around The Vineyard

Rinieri of Rinieri S.R.L. said that the main factors

Van Hoorn said vineyards should, “Switch to an to consider are the size of the vineyard and row

electric shear before the labor market chews you width.

up and spits you out!”

“When a vineyard is large in size, it needs a quick

Killion of Zenport reminded vineyard managers machine, like Bio-Dynamic, TURBO or TURBO EVO,”

that pruning tools are used extensively, and bat- she said. “If it is small, it can use EL, FS or EP. Also,

tery-powered pruners, in particular, need to be ser- finding out what type of work a vineyard wants

viced periodically. to do is important because some machines can

use different working heads, like TURBO EVO and

“Choose a manufacturer that stocks replacement TURBO, with no power tools. The width of the row

parts, like blades and bumpers,” Killion said. “For is important because all machines have a range of

electric pruners, it is imperative that a service cen- widths in which they can work.”

ter with quick turnaround is available.”

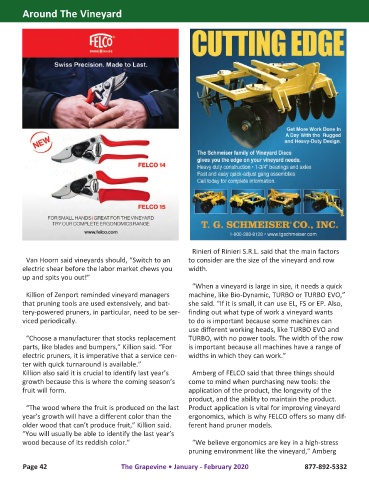

Killion also said it is crucial to identify last year’s Amberg of FELCO said that three things should

growth because this is where the coming season’s come to mind when purchasing new tools: the

fruit will form. application of the product, the longevity of the

product, and the ability to maintain the product.

“The wood where the fruit is produced on the last Product application is vital for improving vineyard

year’s growth will have a different color than the ergonomics, which is why FELCO offers so many dif-

older wood that can’t produce fruit,” Killion said. ferent hand pruner models.

“You will usually be able to identify the last year’s

wood because of its reddish color.” “We believe ergonomics are key in a high-stress

pruning environment like the vineyard,” Amberg

Page 42 The Grapevine • January - February 2020 877-892-5332

Grapevine Main Pages GV010220_Layout 1-1 .indd 42 12/20/19 3:17 PM